Ama-Manifold Freeze Dryers

Uhlolojikelele lwe-Manifold Freeze Dryers

Isomisi esiqandisiwe esiphindaphindwe kaningi sivame ukusetshenziswa njengesisetshenziswa sokungena ekumisweni yiqhwa.Abacwaningi abafuna isithako esisebenzayo somuthi noma ukucubungula izingxenyana ze-HPLC bavame ukusebenzisa okomisa okomisa okuhlukahlukene phakathi nezinyathelo zabo zokuqala elebhu .Isinqumo sokuthenga lolu hlobo lwesikomisi sokuqandisa ngokuvamile sisekelwe kumibandela ehlanganisa, kodwa asikhawulelwe kulokhu:

1. -Inani labasebenzisi elebhu ngokuvamile liphezulu futhi inani lomkhiqizo abawenzayo lincane

2. -Izinombolo ezinkulu zamasampuli amancane ngamanye

3. Isabelomali semishini emincane

4. Uhlobo lwamabhange omakhalekhukhwini

5. Friza umkhiqizo omisiwe hhayi ukusetshenziselwa ukuhweba kulesi sigaba

6. Ucwaningo lwesigaba sokuqala kakhulu

7. Ukucutshungulwa komkhiqizo okubaluleke kakhulu kuyadingeka

Nakuba kuthengwa inqwaba yezinhlelo eziningiliziwe futhi iwanele umsebenzi owenziwayo, kubalulekile ukuqonda ukuthi ukusebenzisa isomisi sokuqandisa esinezinhlobo eziningi kunemikhawulo ebalulekile mayelana nenqubo yokumisa iqhwa.Ekugcineni u-opharetha akakwazi ukulawula inqubo yokumisa iqhwa, njengoba bebengenza ethreyini ebiza kakhulu futhi eyinkimbinkimbi noma isomisi sokuqandisa seshalofu.Kodwa-ke, kunezinyathelo ezingathathwa ukuze kwakhiwe impumelelo enkulu kumshini wokomisa umshini wokuqandisa lapho kusetshenziswa leyo nto.Lesi sihloko sizochaza amasistimu ayisisekelo amaningi, ukulinganiselwa kwawo namandla kanye nendlela yokunciphisa ezinye zezinkinga ezingase zenzeke phakathi nenqubo yokumisa iqhwa.

Ukuqonda Izingxenye Zokomisa Iqhwa Okuningi

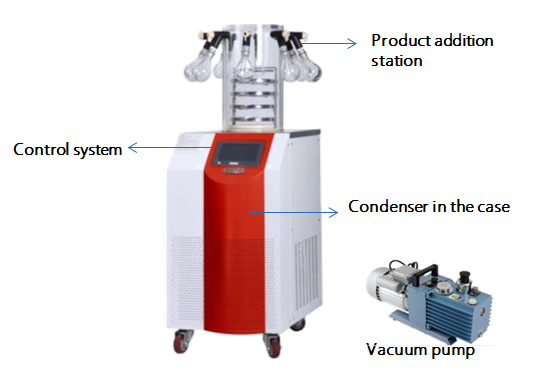

Njengazo zonke izinto zokomisa umshini wokomisa umshini wokomisa izikhathi eziningi zinezingxenye ezi-4 eziyisisekelo.Lezi izi:

· Isiteshi sokwengeza umkhiqizo

· I-Condenser

· Vacuum

· Control System

Isiteshi Sokwengeza Umkhiqizo

Isiteshi sokwengeza umkhiqizo siwucezu lwempahla eyethula umkhiqizo emshinini wokuqandisa.Endabeni yesistimu ehlukahlukene iziqukathi zomkhiqizo ngokuvamile zingamaflaski.Umkhiqizo ufakwa kufulaski futhi ngokuvamile uqandiswe ngokwezibalo endaweni yokugeza enezinga lokushisa eliphansi noma efrijini.Sizoxoxa ngezinketho zokuqandisa ngokujula okwengeziwe ngokuhamba kwesikhathi kuleli nothi lobuchwepheshe.

I-Condenser

I-condenser cishe kuzo zonke ezomisa iqhwa zesimanje iyindawo eqandisiwe esebenza ukushayela inqubo ye-sublimation ngokwenza

indawo yokucindezela ephansi ku-dryer.I-condenser iphinde isebenze ekucupheni umswakama/izincibilikisi futhi ngaleyo ndlela ivimbele ukuthi baye empompini ye-vacuum.Imishini yokumisa iqhwa eminingi inikezwa "esiteji esisodwa"

(i-compressor eyodwa), "isiteji ezimbili" (ama-compressor amabili) noma "isiteji esihlanganisiwe" (ama-compressor amabili anenhlanganisela ekhethekile yegesi).Amazinga okushisa aphansi aphezulu - 48C (kuyunithi yesiteji esisodwa) kuya -85C (uhlelo lwesiteji ezimbili) ajwayelekile.Amanye amasistimu ahlanganisiwe angafinyelela ngisho namazinga okushisa aphansi, njenge -105C.Kubalulekile ukuqonda ukuthi umfutho womhwamuko phezu kweqhwa awulona ijika eliwumugqa.Njengoba izinga lokushisa liyehla futhi lehla umthetho wokunciphisa ukubuyisela uyasebenza.

I-Vacuum yesistimu kanye ne-Vacuum Pump

Ingcindezi yomhwamuko phezu kweqhwa ku-48C ilingana no-37.8 mT.Ku-85C kungu-0.15 mT okusho umehluko cishe ongama-37.65

mT.Ungabona nokho ukuthi ngaphansi -85C izinga lokushisa eliphansi lidala kuphela ukwehla okuncane kakhulu okukhuphukayo kokucindezela -kweshumi kanye nekhulu lekhulu le-milliTorr.Ngempela, ukucindezela komhwamuko okuningi phezu kwamatafula eqhwa ashicilelwe kuma cishe ku -80C ngoba emazingeni okushisa aphansi umehluko wengcindezi uba yinto encane.

Iphampu yevacuum yezindawo zokomisa iqhwa eziningi eziyizigaba ezimbili iyiphampu yokuvala enguwoyela ejikelezayo enezigaba ezimbili.Inhloso eyodwa yamaphampu we-vacuum ngesikhathi senqubo yokumisa iqhwa ukususa imihwamuko engajiki (i-nitrogen, umoya-mpilo, i-carbon dioxide et al) emshinini wokomisa.Ngokukhipha amagesi angacondensable ohlelweni iphampu yevacuum isiza kakhulu ukudala indawo yokunciphisa i-sublimation (iqhwa liye kuhwamu ngaphandle kokudlula esigabeni soketshezi)

ukwenzeka.Ngoba zonke izinto zokomisa iqhwa zinokuvuza (ukuvuza okungokoqobo-ukuphuma kwensimbi engagqwali (yebo kungase kuphume), ama-gaskets, ama-acrylic et al kanye nokuvuza kwamaphinikhodi angempela-okuncane kokucushwa okuhlukahlukene nezindawo ngaphakathi kohlelo, okufana neshubhu ye-vacuum exhuma phakathi. i-condenser kanye nephampu yevacuum) iphampu yevacuum isebenza ngokuqhubekayo kuwo wonke umjikelezo wokumisa okuyiqhwa.Ngokwethiyori UMA okomisa okomisa bekungavuzi ngokuphelele futhi kungavuzi ngokuphelele, lapho iphampu ye-vacuum yenze ukudonsela phansi kokuqala ibingacishwa futhi ingaphinde isetshenziswe kuze kube sekupheleni kokugijima.Empilweni yangempela lokhu akunakwenzeka.

Uhlelo Lokulawula

Uhlelo lokulawula umshini wokomisa iqhwa luya ngokuya lubaluleke kakhulu ekuhlukaniseni umshini wokomisa oyiqhwa owodwa kwesinye.Inani le-automation kanye nobungane bomsebenzisi lingahluka kakhulu ukusuka komunye umshini kuya komunye.Kungakhathalekile uhlobo lomkhiqizo, kuyanconywa ukuthi ukuvala okuzenzakalelayo nokuzenzakalelayo kuyingxenye yamakhono esilawuli.Kulabhorethri lapho okomisa okuhlukahlukene kuvame ukusetshenziswa kakhulu, ukomisa iqhwa kuyindlela yokuphela futhi enye inqubo ohlwini olude lwezinqubo okufanele abantu bazisebenzise ukufeza izinhloso zabo.Akuwona wonke umuntu oyingcweti yokomisa iqhwa.Ukuba nemisebenzi ezenzakalelayo yokuvula nokuvala kusiza ukuqinisekisa ukuthi ukulandelana okufanele kokuqalisa kanye nokuvala shaqa kusetshenziselwa ukunikeza ukuvikeleka kwesistimu nokuphila isikhathi eside.

Isikhathi sokuthumela: Jan-21-2022